Your Plant Is Your Process: Why Facility Performance Is the Next Frontier in Manufacturing Efficiency

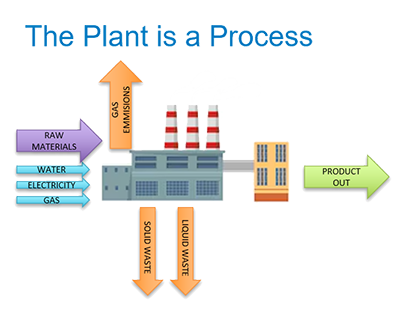

Most manufacturers invest heavily in optimizing their production lines—while overlooking the largest process at their site: the plant itself.

For maintenance and operations teams, the plant is your process, and its performance has a direct impact on costs, sustainability, and overall equipment effectiveness (OEE).

Treating the plant with the same rigor as a production line is one of the fastest ways manufacturers can reduce waste, improve reliability, and strengthen profitability.

The Industrial Sustainability Equation Defines Every Process at the Facility

Every process and facility is governed by the same equation:

[RAW MATERIAL] + [ENERGY] + [LABOR] – [SCRAP] = [FINISHED GOODS]

Production lines are affected by each of these variables—but so is the facility.

Plant energy consumption, water use, compressed air losses, waste streams, and building inefficiencies all impact your bottom line just as much as process-level adjustments.

Many organizations monitor their production processes with high levels of metrology in great detail while assuming the plant will “just work.” That mindset comes at a cost.

Process Lines Are Instrumented. The Plant Often Isn’t.

Modern production lines bristle with instrumentation:

- Temperatures

- Pressures

- Flows

- Cycle times

- Speeds

- Quality and performance data

These metrics fuel improvements in OEE:

OEE = Availability × Performance × Quality

But while the process is monitored down to the finest of detail, the plant itself is often measured only during annual PMs or occasional utility reviews. Critical W.A.G.E.S. (water, air, gas, electricity, steam) data is missing—or incomplete. Leadership doesn’t always see the value in monitoring it.

This is like visiting the doctor once a year but ignoring what your body tells you every day.

Your Facility Sends Signals—Are You Measuring Them?

Your plant offers constant feedback on its health:

- Daily energy and water usage

- Weekend vs. weekday consumption patterns

- Shift-to-shift performance differences

- Seasonal impacts

- Electrical harmonics and power quality

- Wastewater volumes and characteristics

- Compressed air supply and losses

- Steam efficiency

When metering and monitoring systems are in place, these signals become visible. Patterns emerge. Baselines form. Operators can instantly see what’s normal and what’s not.

With the right data, you can answer critical questions:

- Is our consumption proportional to production?

- Where are we wasting energy or utilities?

- Are our systems running "in" control?

- What does “good” look like for our facility?

This level of insight transforms plant operations from reactive to proactive—and directly improves sustainability and performance.

Why Facility Monitoring Creates a Competitive Advantage

Treating your plant as a process delivers measurable benefits:

✔ Lower operating costs

Identify energy waste, leaks, and inefficiencies before they become expensive.

✔ Higher OEE

Utility reliability directly affects availability and performance.

✔ Stronger sustainability metrics

Track and provide reductions in energy, water, and waste.

✔ More predictable operations

Patterns help operators anticipate issues before failures occur.

✔ Faster leadership buy-in

Data builds the business case for upgrades, repairs, and capital projects.

When the plant runs as efficiently as the production lines, the entire organization wins.

Where to Start: Build a Foundation of Measurement

A modernization effort begins with metrology—adding the right instrumentation to track what goes into and out of the plant:

- Electricity

- Water

- Natural gas

- Compressed air

- Steam

- Wastewater and effluent

- Emissions and waste

With proper data collection, facility performance becomes visible for the first time. Operators can quickly see whether the plant is running in control and make adjustments just as they would on a production line.

Bring in Expertise When Needed

Even when funding is secured, internal teams often struggle to dedicate time to plant-wide monitoring projects. This is where a partner with multidiscipline experience can help.

Matrix Technologies has delivered facility metering, monitoring, automation, and sustainability solutions across a wide range of industries. We help plants:

- Select and install metering systems

- Integrate W.A.G.E.S. data into existing control systems

- Build dashboards and analytics

- Automate alerts and reporting

- Identify efficiency and sustainability opportunities

Continuous improvement is a team effort—and you don’t have to tackle it alone.

Your Plant Is the Process. Optimize It.

Efficiency and sustainability share the same goal: Doing more with less.

By viewing your plant as a process—and giving it the same level of instrumentation and attention as your production lines—you unlock new opportunities to reduce waste, improve reliability, and boost profitability.

If you're ready to modernize your facility’s performance, Matrix Technologies can help you get started.