Sealing the Craft: Engineering the Bottling of Spirits - Part 7

The previous article discussed maturation of the spirit. This article will discuss the next and final step in the spirits production flow; bottling.

Technical Background

Before bottling (and possibly before barreling), spirits are mixed with water to reach a specified proof point. Water used to cut the spirit is typically filtered to high quality, sometimes employing reverse osmosis (RO) filtration.

The process of bottling and labeling can range from fully manual to fully automated. Some small facilities make bottling an event and invite the public for help. Depending on the size of the distillery and available labor, various levels of automation can be incorporated into bottling as well as the rest of the spirit making process.

How Matrix can help

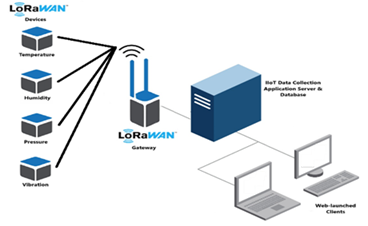

The climate for oak barrel storage can affect the aging and quality of spirits, which can affect the bottom line and brand reputation of a distiller. Matrix can provide a wireless network of IIoT (Industrial Internet of Things) sensors to monitor the barrel warehouse climate for compliance and send alarms via email or text for out of tolerance conditions. The monitoring and data collection solution is a secure, wireless, low power, long range, and non-invasive answer to centralized monitoring of all warehouse climates that is quickly deployed and easily scaled.

Figure 1: IIoT Monitoring System Architecture

In the bottling and packaging areas, it is critical to maintain an efficient bottling/packaging process to keep your operations on track and orders fulfilled. Matrix has helped various distillers with OEE (Overall Equipment Effectiveness) monitoring which provides both OEE key performance indicators and asset performance monitoring. Knowing the real-time performance of filling, bottling, and packaging operations is crucial to meeting timely order fulfillment and scheduling production runs.

Figure2: OEE Dashboards

OEE metrics

are comprised of 3 key performance indicators; Availability x Performance x Quality = OEE measured as a percentage.

Matrix delivers solutions to measure key performance, availability, and quality KPIs to determine bottling line efficiency and measure downtime. This crucial information helps to:

- Improve production output

- Improve response time to problems

- Manage Work In Progress (WIP)

- Schedule production orders

- Capture equipment downtime reasons

- Consistently disseminate timely and accurate production data

- Involve bottling line personnel in continuous improvement

A comprehensive OEE system helps Distillers understand and track their baseline and provide the data to maintain and improve their operational efficiency. You cannot improve what you cannot measure. We have seen customers start with a 60% OEE and be able to resolve downtime and performance issues to get their OEE into the 80% range.

Conclusion

From grain receiving to bottling, spirits production employs many aspects of design engineering. Next time you join a distillery tour or raise a glass in celebration, take an extra minute to appreciate all the reactions, thermodynamics, and separations that lead to your libation. If you represent a distillery in need of help, please consider Matrix as a trusted partner for your next project.