Refining the Spirit: Engineering Distillation for Purity and Safety - Part 5

The previous article discussed the biological process of fermenting sugary liquid into low alcohol wort (or wine, beer, or cider). This article will discuss the next step in the spirits production flow, distillation.

Technical Background

The distillation process will refine and concentrate the fermented liquid into a spirit. Distillation can be done in batches or in a continuous column still. The concept is the same: heat the liquid to allow ethanol to boil off. Ethanol has a lower boiling point than water so water and any impurities, like remaining organic matter, will collect at the bottom of the still while the low boiling point components, like ethanol, evaporate.

However, not all the vaporized product is usable as a spirit. The wash boils off in series as heads, hearts, and tails. The most volatile components of the wash, like methanol, boil off first in the heads. Heads can be used for cleaning in the distillery but are dangerous to consume. Next, the hearts boil off, which is the liquid that will eventually be sold as spirits. The last of the vaporized products is called the tails. These are larger molecules that will typically be recycled back into the distillation process to extract any available ethanol. The cuts between heads, hearts, and tails, is a decision made by science and art by the owner’s master distiller.

The vaporized ethanol is condensed, collected, and cooled. Sometime this happens multiple times in series to reach the owner’s desired proof. The collected ethanol is always clear regardless of the base material.

The beer leaving the fermenters is usually measured in alcohol by volume (ABV) and can range from 5-12%. The distilled spirit leaving distillation is typically measured in proof, which is twice the ABV.

Alcohol by volume (ABV) *2 = proof

Stills are traditionally constructed of copper. The initial advantages of copper construction were physical. Copper is ductile and malleable, making it relatively easy to construct into various shapes. Copper also has a high thermal conductivity, which provides efficient heat transfer and even heat transfer, avoiding hot spots. Copper at 68°F has a thermal conductivity of 232btu/ft-h-°F. For comparison, Stainless steel 304 at 68°F has a thermal conductivity of 8 btu/ft-h-°F. (Engineering Toolbox)

More recently, copper has been identified to improve the flavor of the distillate. “Copper aids in the removal of undesirable components, especially sulfur, which imparts an off flavor to the distillate.” (Jacques) Modern stills can be a hybrid of stainless steel and copper to take advantage of copper’s sulfur reactions with the durability and cost advantage of stainless steel.

Heat provided to distill a spirit comes from steam. Steam boilers are available that run on natural gas, coal, or fuel oil. Sustainable minded distilleries may opt for boilers that run on electricity with the option to run on renewable electricity either generated on site or coordinated with the utility supplier. In most distilleries, the stills are uninsulated, which allows energy loss to the surrounding atmosphere. It is possible to insulate a still to increase energy efficiency.

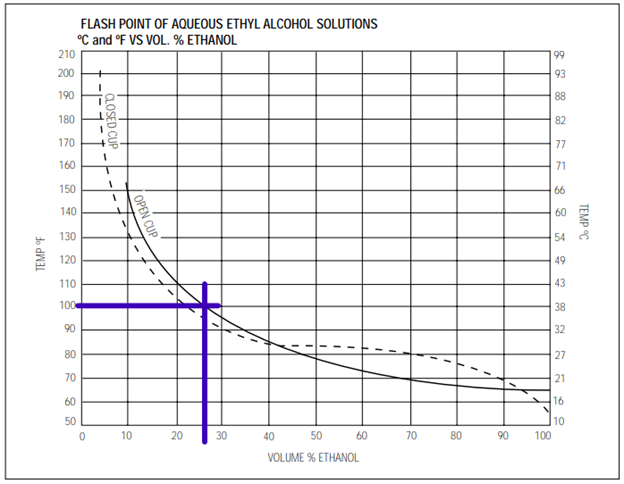

PSM applies to “a process which involves a Category 1 flammable gas (as defined in 1910.1200(c)) or a flammable liquid with a flashpoint below 100 °F (37.8 °C) on site in one location, in a quantity of 10,000 pounds (4535.9 kg) or more.” (US Department of Labor) The criteria excludes flammable liquids stored in atmospheric storage tanks remote from the process but includes collective volume within a process. Let’s assume the distillate from the final distillation run is 140 proof or 70% ABV. A solution of 70% ethanol has a flash point around 70°F, which is below the PSM criteria of 100°F. If 10,000 pounds (or ~1,350 gallons) of 140 proof spirit is stored in one or collectively in several containers, the system qualifies for OSHA’s PSM. The containers could include the top of the still, condensers, interconnecting piping, and storage tanks (like a bottling or proof tank) close to the still.

Once ethanol reaches beyond ~25% ABV (50 proof), the flash point of the mixture falls below 100°F. If greater than 10,000lbs of the mixture is present in the system, the system qualifies for OSHA PSM.

Figure 1: An ethanol mixture of approximately 25% by volume has a flash point of 100°F, making the mixture eligible for PSM compliance if 10,000 pounds or more are stored. Chart by (Equistar Chemicals LP)

OSHA has provided an interpretation letter that states, “although distillers are required to comply with the PSM standard, OSHA is not enforcing and will not enforce the PSM standard with respect to processes in distilleries and their related facilities…, except in the event of a fatality or catastrophe involving a process that uses ethyl alcohol in a distillery or related facility.” (United State Department of Labor) However, the absence of enforcement does not mean an absence of risk or hazard. It is responsible engineering and operational practice to abide by safety standards.

How Matrix can help

Matrix has extensive design experience with steam and condensate including stress analysis. For additional reading on pipe stress, please see this set of articles by subject matter expert, Chris Mach: Pipe Stress 101 – What is Thermal Expansion and How Does it Create Problems in Piping

Process Hazard Analysis (PHA) reviews are an important step for any project to document, quantify, and mitigate any potential hazards. This process is recommended at least once during design and as needed to comply with OSHA standards after construction. Matrix Technologies is qualified to facilitate a PHA and generate a report. Distilleries can also opt to have a 3rd party facilitate the PHA, in which case Matrix would be pleased to attend and participate to ensure the design includes all safety measures.

In addition to OSHA requirements, the elevated concentration of ethanol in and around the distillation system triggers building code requirements governed by both federal and local standards. Depending on the owner’s insurance provider, even more stringent regulations may apply. To help navigate these complexities, Matrix Technologies offers extensive expertise in conducting architectural code reviews.

Our team evaluates chemical data, building size, and applicable regulations to identify and mitigate life safety hazards. Outcomes of the review may include recommendations for installing a fire sprinkler system, enhancing building ventilation, implementing spill containment measures, or limiting the volume of stored chemicals within designated areas.

The next article in the series will discuss maturation of the spirit.

References:

Engineering Toolbox. https://www.engineeringtoolbox.com/thermal-conductivity-metals-d_858.html. n.d. 27 January 2025

Jacques, Lyons, Kelsall. The Alcohol Textbook 4th Edition. Nottingham: Nottingham University Press, 2003

US Department of Labor. n.d. <https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.119>

Equistar Chemicals LP. Ethyl Alcohol Handbook 6th Edition. 2003.

United State Department of Labor. “Occupational Safety and Health Administration Interpretation Letter.” 14 March 2003. https://www.osha.gov/laws-regs/standardinterpreta-tions/2003-03-14

© Matrix Technologies, Inc.