Engineer-Procure-Construct (EPC) projects involve employing one firm to provide most or all the services required to complete a project. Previously, manufacturers would manage their projects with in-house talent, creating the need for large engineering staffs to manage a number of engineering and contracting partners. As manufacturers are now relying more heavily on outside engineering specialties and project management to complete their projects, the use of this project delivery method is growing in popularity.

The Benefits of EPC

EPC projects are typically run by a single entity, resulting in a number of benefits to the manufacturer. First, having one firm in charge alleviates the need to coordinate many different firms, information flow, schedules, and budgets, which are all aspects of a job that are typically run by a manufacturer’s project engineering group. This not only minimizes distraction for the manufacturer’s engineering team, but it also reduces overall oversight effort by eliminating unnecessary layers of management. The EPC firm can manage and procure multiple bids, reduce bid lag time, and optimize schedules by coordinating equipment and fabrication lead times with engineering effort.

Streamlining management of the project also saves time and money. EPC projects typically set a guaranteed maximum price, reducing budget risks to the owner. With a guaranteed maximum price, it is incumbent on the EPC firm to value engineer the project to meet the price and reduce time-consuming changes to the project, which they do while still meeting the original project goals.

EPC Approaches

There are many ways to approach an EPC project, depending on the desire of the manufacturer. In some instances, an owner may want the EPC firm to meet a certain performance specification (i.e. manufacture 100 units/hour) and request a competitive bid up front to provide this process. This method of EPC is sometimes called “turnkey” or “design-build.” Because there is very little definition to determine pricing, this method is typically the least cost-effective for the owner and most risky for the EPC firm.

Another method is EPCm, or engineer-procure-construct-manage. In this method, the EPC firm will provide design and procurement bid services, but the owner will procure all equipment and contractors. The EPC firm then provides construction management to coordinate the project installation. This method reduces the cost of the project typically by the cost of markup on procured items but adds management effort and contract risk to the owner.

EPC projects are typically most successful when they are run in a progressive manner (Progressive EPC). For a minimal cost, the EPC firm would provide preliminary engineering to establish design parameters and set a budget for the project. The owner could then decide to move forward with the project based on this budget or modify the scope of the project to meet their needs. When the project is then approved and moves to a new contract for detailed design, the budget is again determined based on more project definition and could be modified based on scope review and value engineering. At the end of detailed design, the EPC firm is then contracted to provide all installation services.

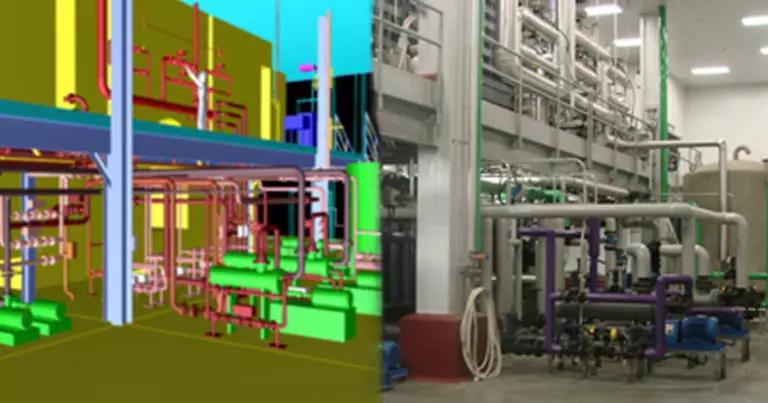

Project delivery from design to reality

The Advantages of Designer-Led EPC

An EPC project can be either designer-led or contractor-led. In a contractor-led EPC project, the contractor completes procurement and installation services in-house or with subcontractors and hires the design firm to provide engineering services. In a designer-led EPC project, the engineering firm will provide engineering services, complete procurement, and complete installation services with subcontractors.

What are the advantages of a designer-led EPC project? Simply put, the designer controls the design, and the contractors involved respond and provide input. This means that a new plant design will primarily consider the equipment and operability of the plant, as opposed to constructability concerns. A designer-led EPC project will typically be led by a multi-discipline engineering firm, providing a cohesive design due to the firms’ ability to internally coordinate. (In a contractor-led EPC project, there are typically multiple engineering firms involved, creating a risk when coordinating between multiple firms.) Finally, in designer-led EPC projects, the engineers coordinate directly with the owner and the owner’s plant personnel, without information being filtered or controlled by others. This leads to a better understanding of the manufacturer’s needs and desires for their plant and process, and typically leads to a better design.

Why Matrix Technologies Is the Best Choice for Your EPC Needs

With designer-led EPC projects, Matrix has a better process for success. Our experienced project team uses a Project Gating Process to ensure timely delivery of services and maximum value. Because our firm offers all of the engineering disciplines, we are able to avoid subcontracting and eliminate multiple layers of management, providing cost savings to our clients and ensuring a smoother process with minimum hassle. Our team has successfully developed complex EPC projects for a variety of industries, including food, beverage, petrochemical, and consumer goods; from projects as simple as refining a manufacturing process to the complex process of building a new facility. With Matrix as your engineering partner, you’ll have everything you need for a successful, start-to-finish EPC project.

Matrix Technologies is one of the largest independent process design, industrial automation engineering, and manufacturing operations management companies in North America. To learn more about our EPC management capabilities, contact Jerry Francis, Associate Director, Project Delivery.

© Matrix Technologies, Inc.