Brewing the Base: Engineering Fermentation in Spirit Production

The previous article discussed converting starch into simple sugar. This article will discuss the next step in the spirits production flow, fermentation.

Technical Background

At this point, a sugary liquid is ready to be converted into alcohol. Yeast is added to the liquid to metabolize the sugars into alcohol and carbon dioxide. The yeast strain is typically proprietary to the owner. The yeast could be wild or cultured, directly pitched into the liquid, or pre propagated in a separate vessel.

Fermentation of glucose follows the following chemical formula:

C6H12O6 → 2C2H5OH + 2CO2

The fermentation process is exothermic and the temperature of the liquid must be carefully controlled. It is possible for the fermentation reaction to increase the fluid temperature to a point of irreversible damage to the yeast. Owners can choose to use jacketed vessels or internal cooling coils in those cases to maintain a desired temperature. It is also possible for the heat from the exothermic reaction to dissipate into the atmosphere without causing a thermal issue, even without external cooling. Overcompensating with external cooling can slow down the yeast activity, which can also be intentional if there are operational outages downstream.

The fermentation vessels could be constructed of wood or stainless steel. They could also be open top or closed top. Open top vessels are popular where a tourism experience is valued by the owner so guests can see the foamy-top fermenter bubbling. Some owners choose to have open top fermenters near open windows to allow the local flora to infuse the fermentation mash and add unique characteristics to the final spirit. An open top fermenter also allows some alcohol to evaporate during fermentation. A closed top fermenter provides a place for that evaporated alcohol to condense and remain in the fermenter.

At the end of fermentation, the liquid is essentially beer, wine, or hard cider depending on the base. Producers that sell beer, wine, or hard cider will filter or otherwise clean the product to ensure it is safe for consumer’s drinkable enjoyment. In a distillery, this low percentage alcohol by volume (ABV) fluid, often called wash, will be further refined into a spirit.

The other product of fermentation, carbon dioxide, is not to be overlooked. Carbon dioxide is a colorless, orderless, non-flammable gas that is denser than air. In high concentrations (such as within a fermenter) CO2 presents an asphyxiation risk. Proper ventilation and gas detection should be installed to provide a safe work environment for employees and guests.

How Matrix can help

Fermentation tanks typically occupy the largest footprint in a distillery. For greenfield distilleries, the arrangement of the tanks and tank construction can be accommodated in the design. For distilleries interested in expanding production, getting a tank into an existing building can create additional challenges.

Matrix has the ability to create a 3D scan of existing facilities with a point cloud and web-based output available to manipulate for design. The results of the 3D scan are also the client’s to keep and can be valuable for training new personnel.

Once the scan is complete, Matrix can design using the scan as the background. Three-dimensional objects such as equipment, piping, platforms, walls, etc. will be added to, or removed from, the model to reflect the project scope. This model can be reviewed with distillery personnel and manipulated from all angles to ensure the needs are met for operations, maintenance, and tourism pathways. The model can also be manipulated to ensure new equipment can fit within the design space, as well as fit through available openings for construction.

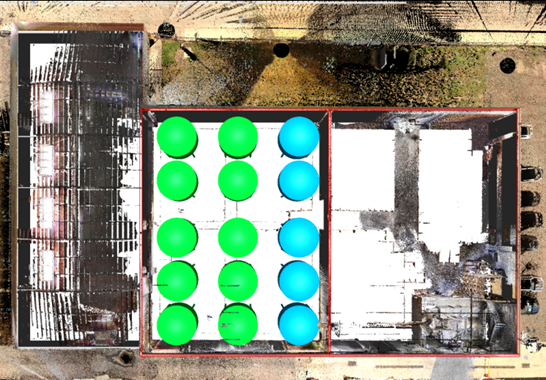

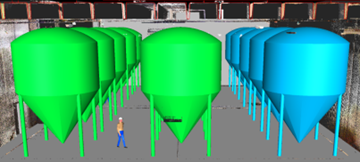

Below is an example of fermentation tanks placed inside of a 3D scan of an existing distillery.

Plan and section views of fermenters modeled with the background of a 3D scan of an existing distillery.

The next article in the series will discuss concentrating and purifying the low ABV liquid into a spirit.