Breaking It Down: Engineering the Processing Stage of Spirit Production

The previous article discussed spirit base materials, and general guidelines on material storage and handling. This article will discuss the next step in the spirits production flow, processing.

Technical Background

The base contains sugars to be fermented into alcohol but typically, in their delivered form, the sugar is inaccessible to yeast. Processing takes different forms depending on the base material and the form of the stored sugar. In figure 2 (in article 1), the classes of spirits are categorized into bases containing complex or simple sugars.

For the bases with simple sugars such as grapes and sugar cane, the base needs to be pressed, shredded, squeezed or crushed to release a liquid ready for fermentation, the extra step for conversion is skipped. Distilleries that manufacture from delivered juice or molasses can skip the processing step.

For bases with complex sugars, the base must be made ready for conversion. Bases of grains and potatoes contain complex sugars in the form of starch. Agave for tequila production contains complex sugar in the form of inulin. Both starch and inulin are carbohydrates composed of smaller glucose and fructose molecules.

The goal of processing a starchy base is to increase the surface area of the raw base. The greater the surface area, the more contact with water and enzymes during the conversion step, which increases sugar availability and later alcohol. Specialty vendor equipment is typically purchased to process the base to a result matching the desired specifications of the end user. The resultant size of the processed base is important – too large may limit the starch available to the yeast for conversion and lower yield (amount of sellable product per mass of base material), too small may cause operational issues if grains clog equipment.

How Matrix can help

As mentioned above, specialty vendor equipment is typically utilized for processing base materials. Matrix works with trusted vendors to specify and design the appropriate processing equipment. Matrix adds value to the processing step with utilities, facilities, and automation.

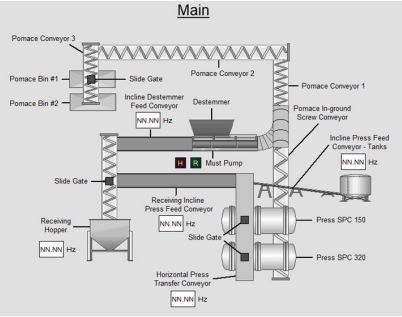

Matrix successfully integrated several pieces of grape crushing equipment supplied by various 3rd party vendors. The vendors supplied hardware to allow for integration, but the pieces of equipment were not supplied ready to communicate with the other pieces of equipment or the plant.

Matrix developed a functional specification to ensure the equipment would be configured, visualized on HMIs, and provide alarms as the client desired. That completed and approved functional specification was then used to design the programmable logic controller (PLC) and human machine interface (HMI) screens. The client was invited to participate in a pre-shipment test; when Matrix and the client test all of the completed programming virtually before installation at the plant to ensure all needs were met and reduce downtime during construction. Matrix also installed the integration systems on site during startup and commissioning of the equipment. This included a site acceptance test; when Matrix tests all of the programming on the live equipment.

After Matrix integrated the equipment, grapes could be bulk unloaded, conveyed, destemmed, crushed, and pressed from a single controller.

The next article in the series will discuss converting the available starch into sugar.